As the front service cabinets have a limit for the height of the led screen, but people still have the requirement for bigger led screen with front service, people become to design front service module. Now there are several method to make front service modules.

2. Using magnet. for indoor use or waterproof modules.

It even more convenient to make front service indoor led screen, as it don’t need special cabinet even no need special modules, just use the magnets to replace the screws, the led screens can have front service because the characters of magnets. This you can have a look at our web page as reference.magnet installation with simple cabinet

For outdoor led screen, the modules need special design to get waterproof:

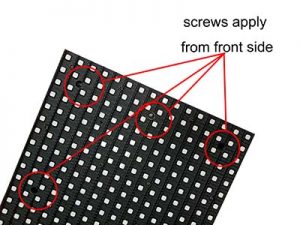

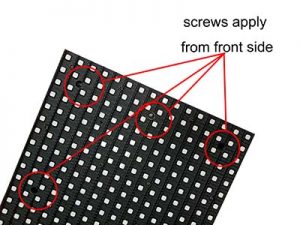

Front service module installed with M3*30 or M4*30 screws

back of the front service module, with several through holes to apply long screws from front side

way to apply screws

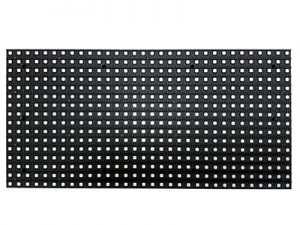

front side of the module

There are also modules installed with special designed fasteners:

The fasteners design canbe different, while the module install method is similar

Now more characteristics have been applied to the front modules, such as IP67 waterproof, 45 degree edge, so the modules can be used for some special led screen, for example, screens with angles or with arc shape, cubic displays.